Seismograph using 3D printed parts making recipe 2023-03-04

My poster presentation at JpGU2022 is here,

以前のポスター発表は以下のとおり.

http://www.yossi-okamoto.net/2022_JpGU-GeoSciEdIX/JpGU_Poster_Seis_2022finalv2.pdf

<Some points to note>

1) Thermal form change

熱による変形に対処するための処置.

PLAやPETGは熱により変形する.PETGの方がややまし.

PLA and PETG are weak to hot temperature, so the long-time form change is a problem.

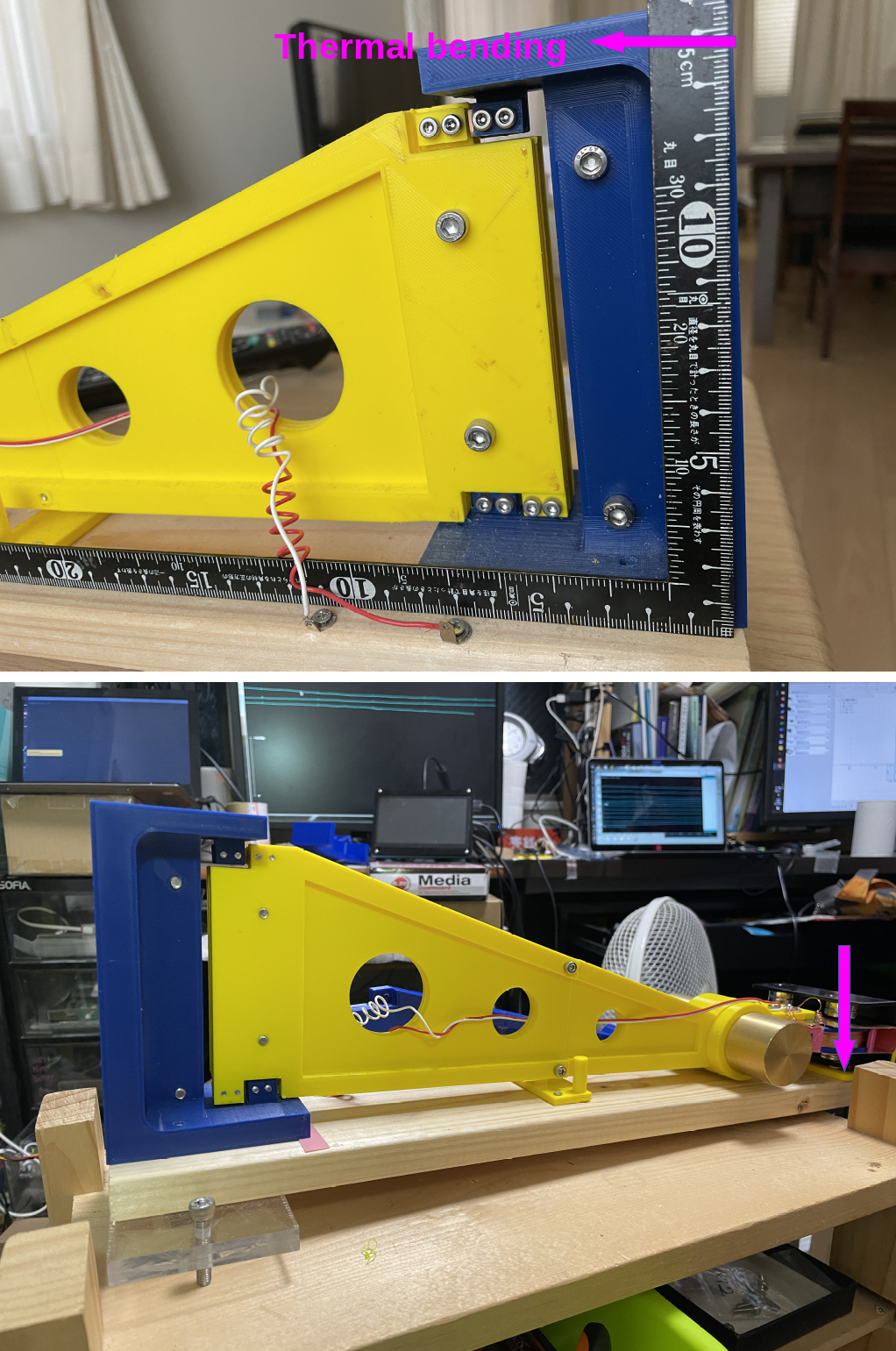

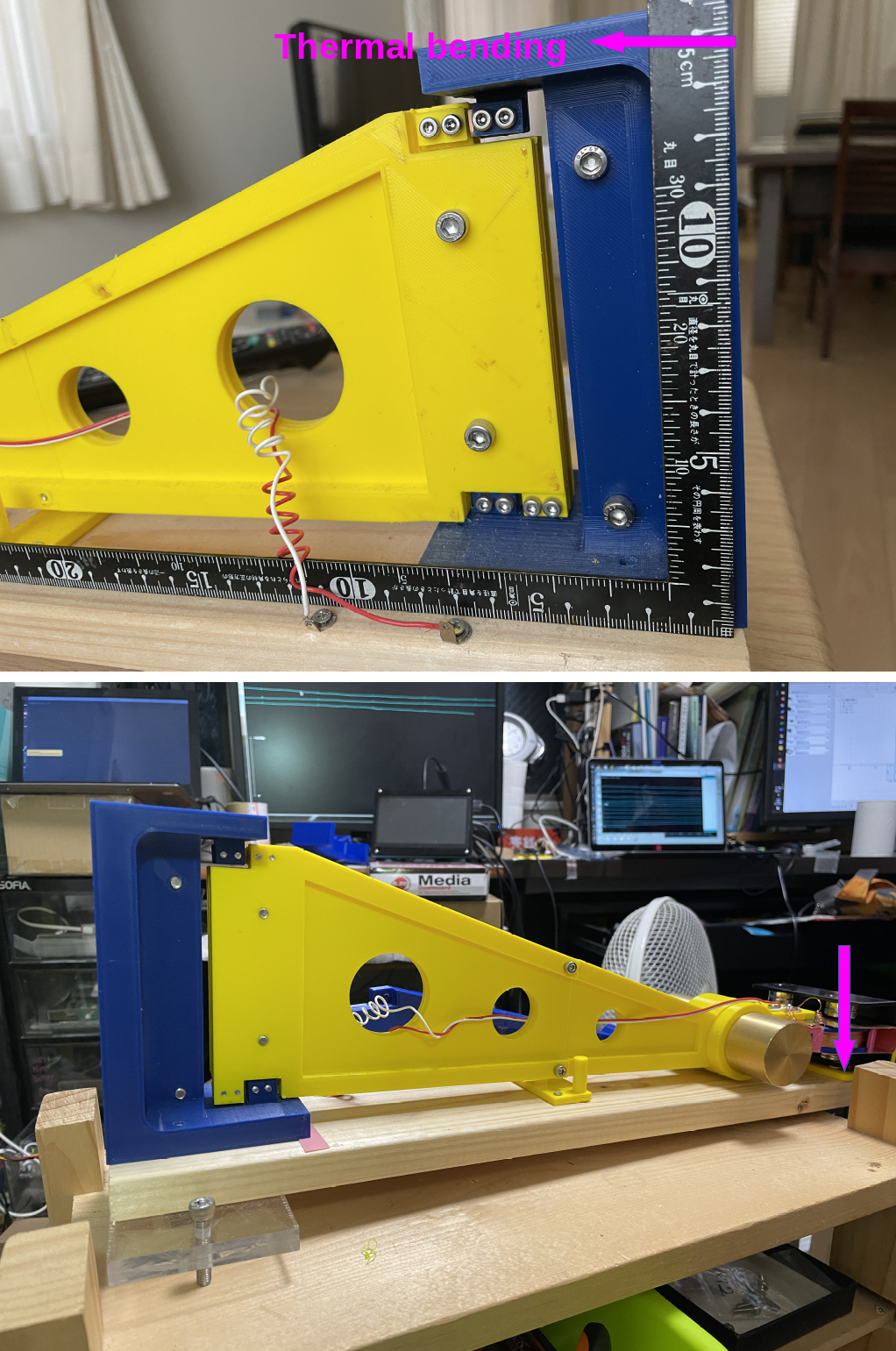

Particularly, the deterioration or the bending of the pendulum and the pillar is a big problem.

Thermal bending of the pillar and you can see the pendulum mass is touched on the bottom.

A solution: to attach acrylic plates to support the pillar against the thermal form change.

Also, the use of PETG rather than PLA at the tropical region is better.

Because the PETG is more withstanding against heat.

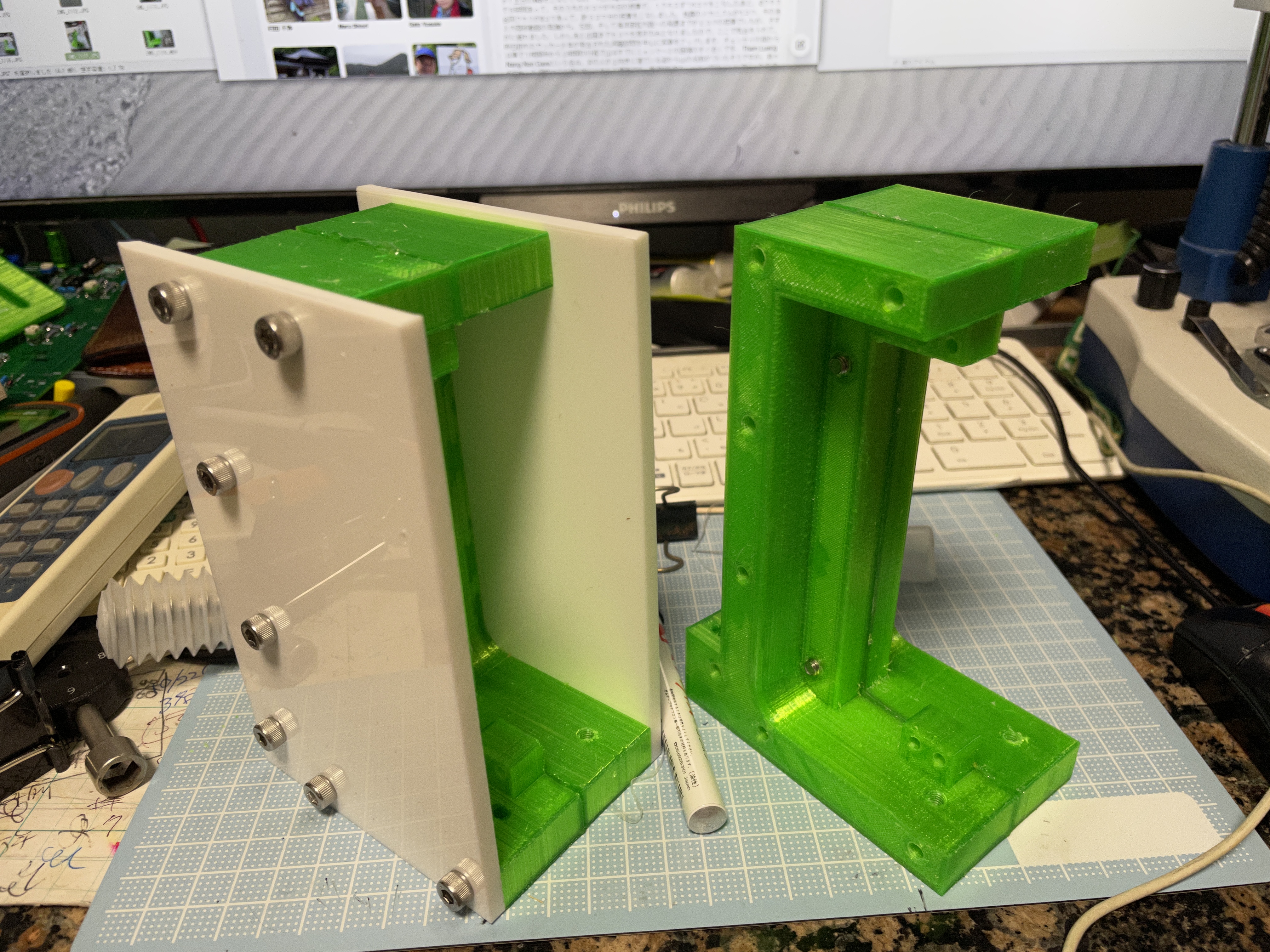

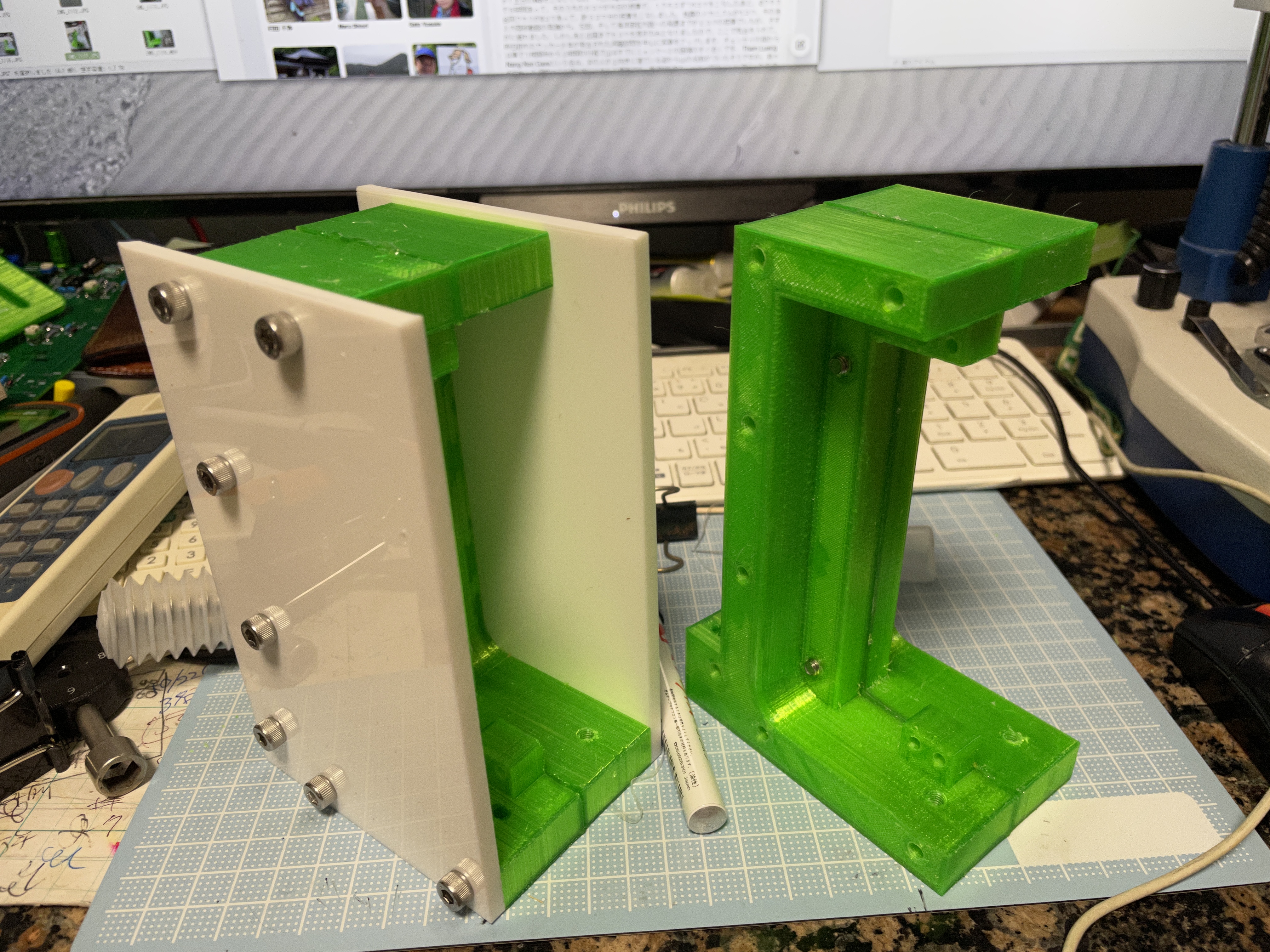

支柱の横にアクリル板を圧着するネジ穴を設ける.

To make bolt holes on the side of the pillars.

A printed pillar. And an assembled pillar.

The final shot.

2)Tapping recipe

ネジ穴製作の注意.

3Dフィラメント製のパーツへのネジ穴開け

The pre-hole is multiplied by 0.8. In other words, a 4mm screw requires a

3.2mm diameter hole, and a 5mm screw requires a 4mm diameter hole.

Sometimes, the holes become smaller due to the thermal printing,

It is better to go through the hole with a drill of the same size before tapping.

・下穴は0.8掛け.つまり4mmビスだと3.2mm,5mmだと4mmの直径の穴を下穴として印刷.実際にはプリント時に内径が少し膨れるので,タップ時に同経のドリルで軽く穴を開けたほうがよい.

When tapping,it is important to take care not in a step forward, but a step backward in order to keep screw trench.

次に,タップするときは,タップを進めるときよりも,抜き去るときにネジ穴を壊しやすい.

i) A through-hole (VIDEO)

貫通孔(動画)

https://youtu.be/tIES4327bi8

ii)A blind hole(VIDEO)

非貫通孔

https://youtu.be/mIsee3kwbUo

Copyright

(c)

Y.Okamoto 2023, all rights reserved.