Photo From Amazon

Photos from Monotaro

https://www.amazon.co.jp/gp/product/B07GBVW57X/ref=ppx_yo_dt_b_asin_title_o03_s00

ダイヤモンド研削盤 #180, #320, 外径180mmx1mm厚 \2000

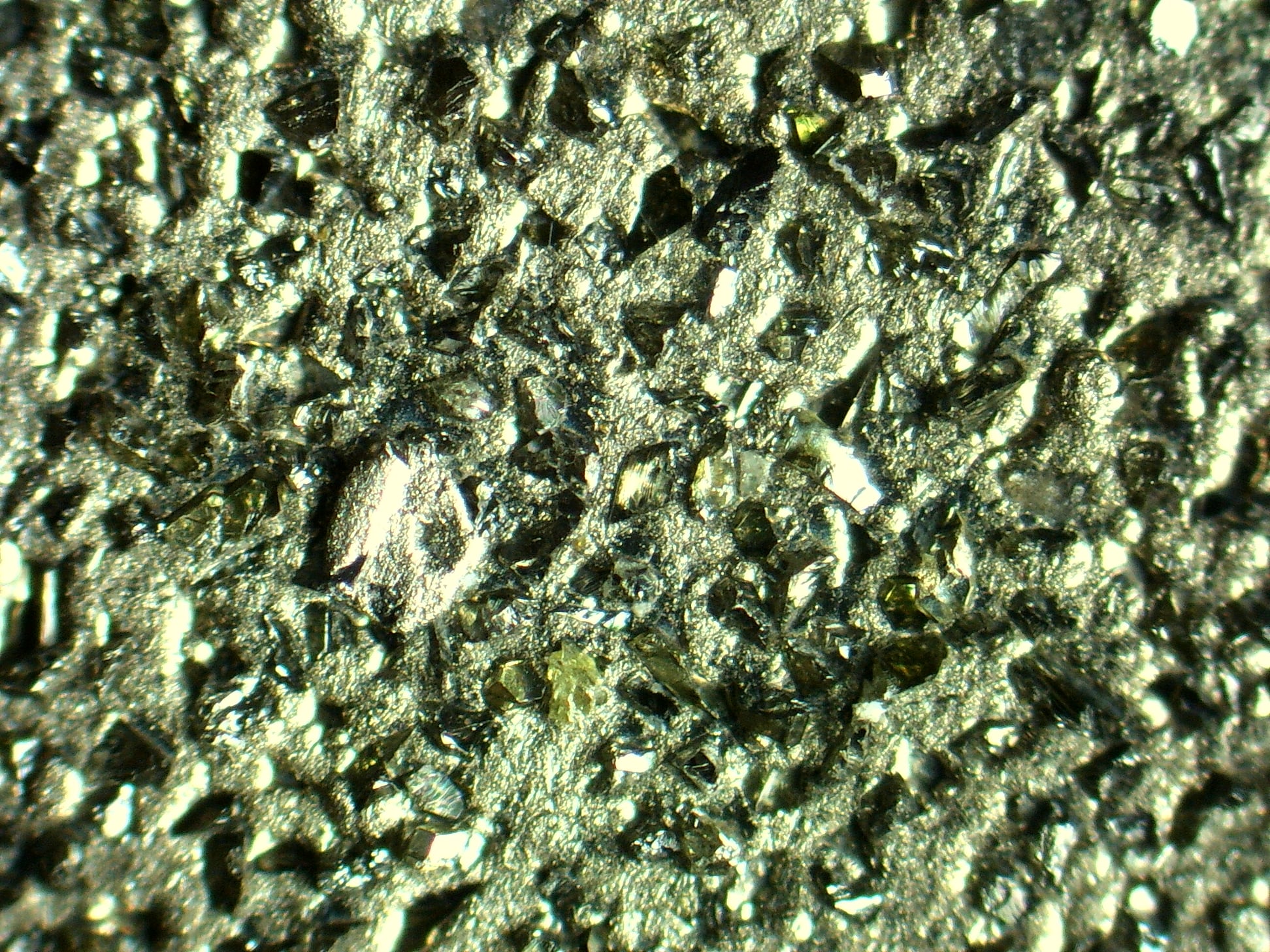

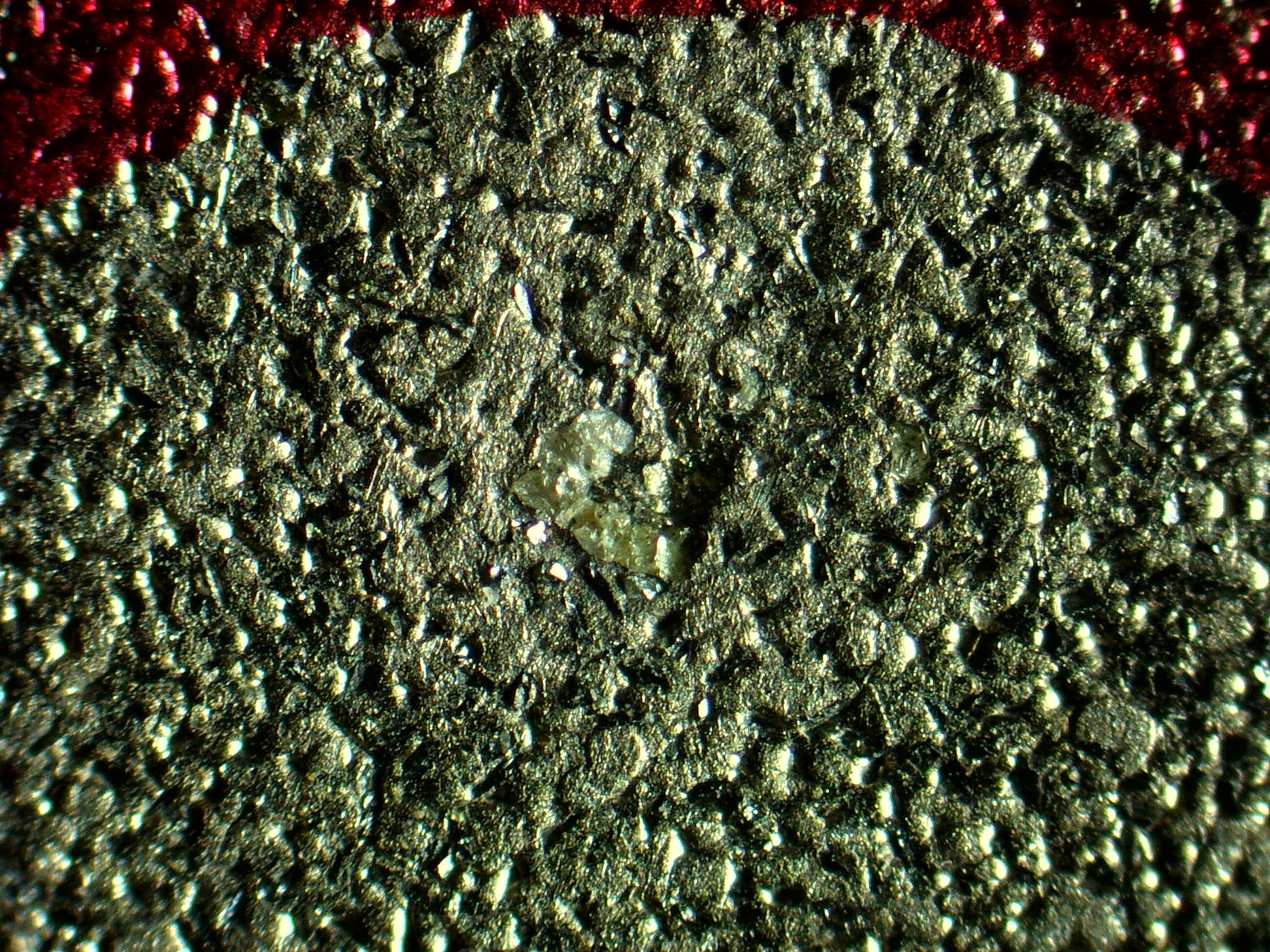

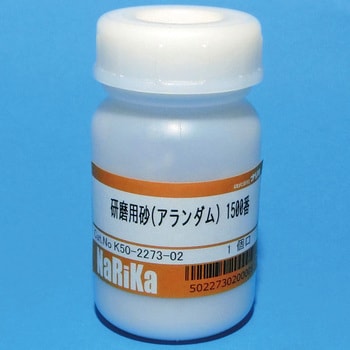

Abrasive: Carborundum #800 500g Alundum #1500 250g about 15-30 USD each

https://www.monotaro.com/g/04473003/

https://www.monotaro.com/g/04473005/

ガラス板(普通ガラス厚板29x19cmx8mm厚,コダマガラスで入手,1枚1000円見当)

研磨剤カーボランダム(#800 500g),アランダム(#1500 少量) モノタロウなどで入手 \3000 \1650