|

|

| Making a water tank from acrylic

plates Cutting by a acrylic cutter and gluing by acrylic glue. We

recommend to use hand gloves for avoiding incision. |

The triangle pillars are used for water proof of the tank. |

|

|

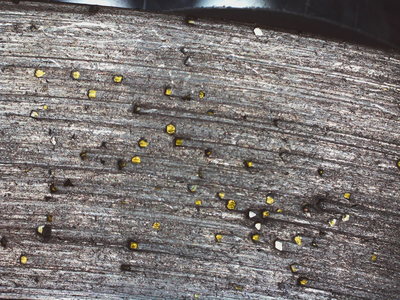

| For a thick pillar of the corners, we used a table-top milling machine. |

Next, cutting to four corner pillars. |

|

|

| These are corner pillars to fix a 3mm aluminum top stage. |

The table and the pillars. A 4mm tap is now making screw holes. |

|

|

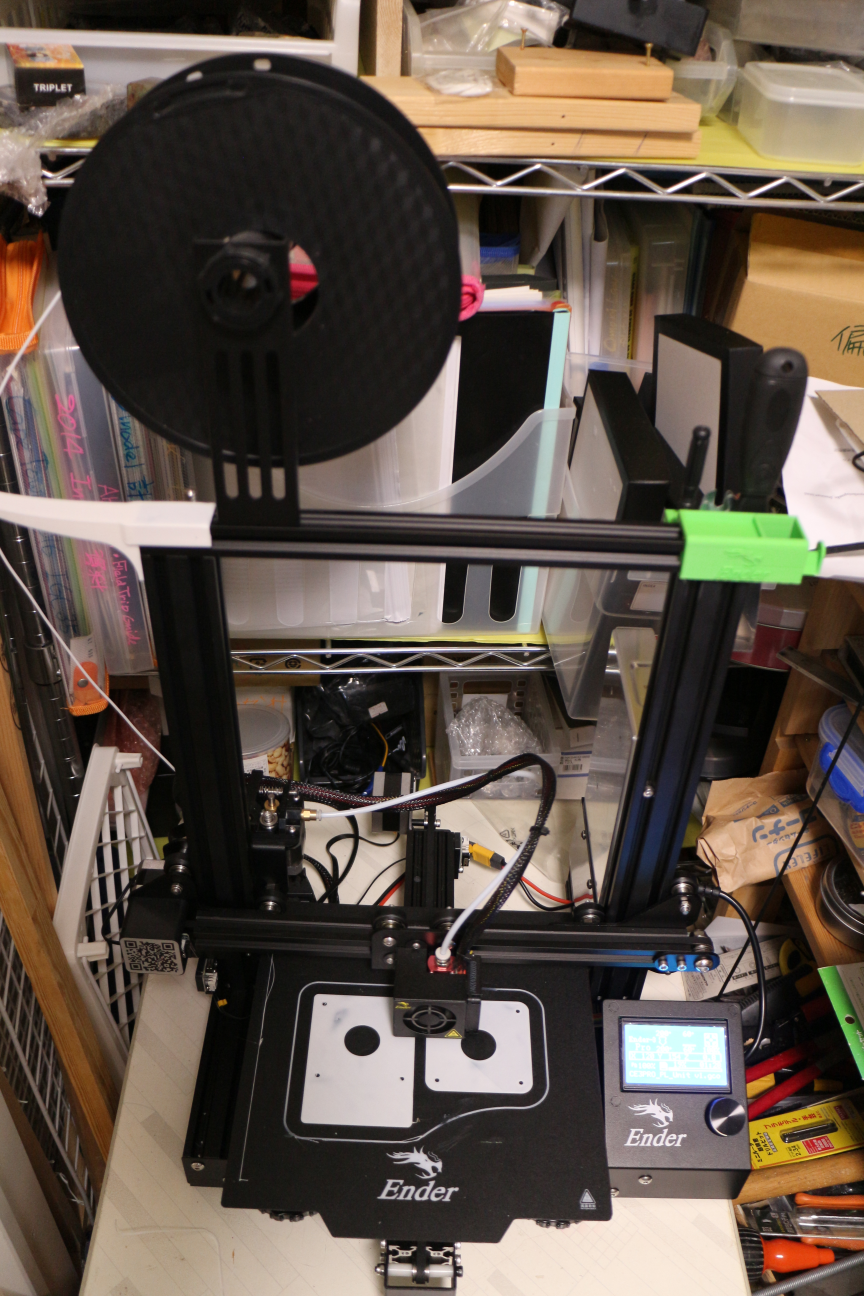

| Using 3D printer, we made a coupled

arbor. The behind aluminum ones are the older version which are made by

using a table lathe. (new photo) |

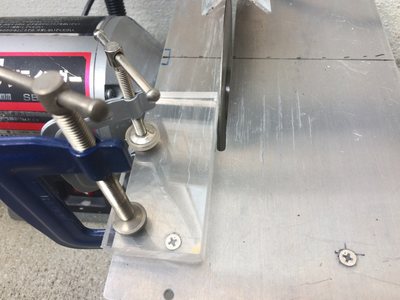

Next, we mill a slit for the diamond blade on the aluminum table (3mm thickness). A 5mm end-mill is used. However, it is not easy to make a straight slit due to machine habit (rotation). |

|

|

| The straight slit is completed. |

All parts are prepared. The water cover is made an aluminum L-shaped bar. |

|

|

| Water tank is fixed by 3 holes to the motor cover and one bolt to the base. |

An arbor is mounted on the motor shat. (new photo) |

|

|

| The diamond blade is mounted as the right rotating direction. The detail is in the following link. http://www.dca.or.jp/di_tools1.html The diamond particles are buried on the iron plate with tails like falling stars. |

We finished mounting the arbors. (new photo) |

|

|

| Two types of the diamond blade, we

can purchase from AliExpress. Their costs are around 10USD. The cutting

quality is almost same by my feeling. |

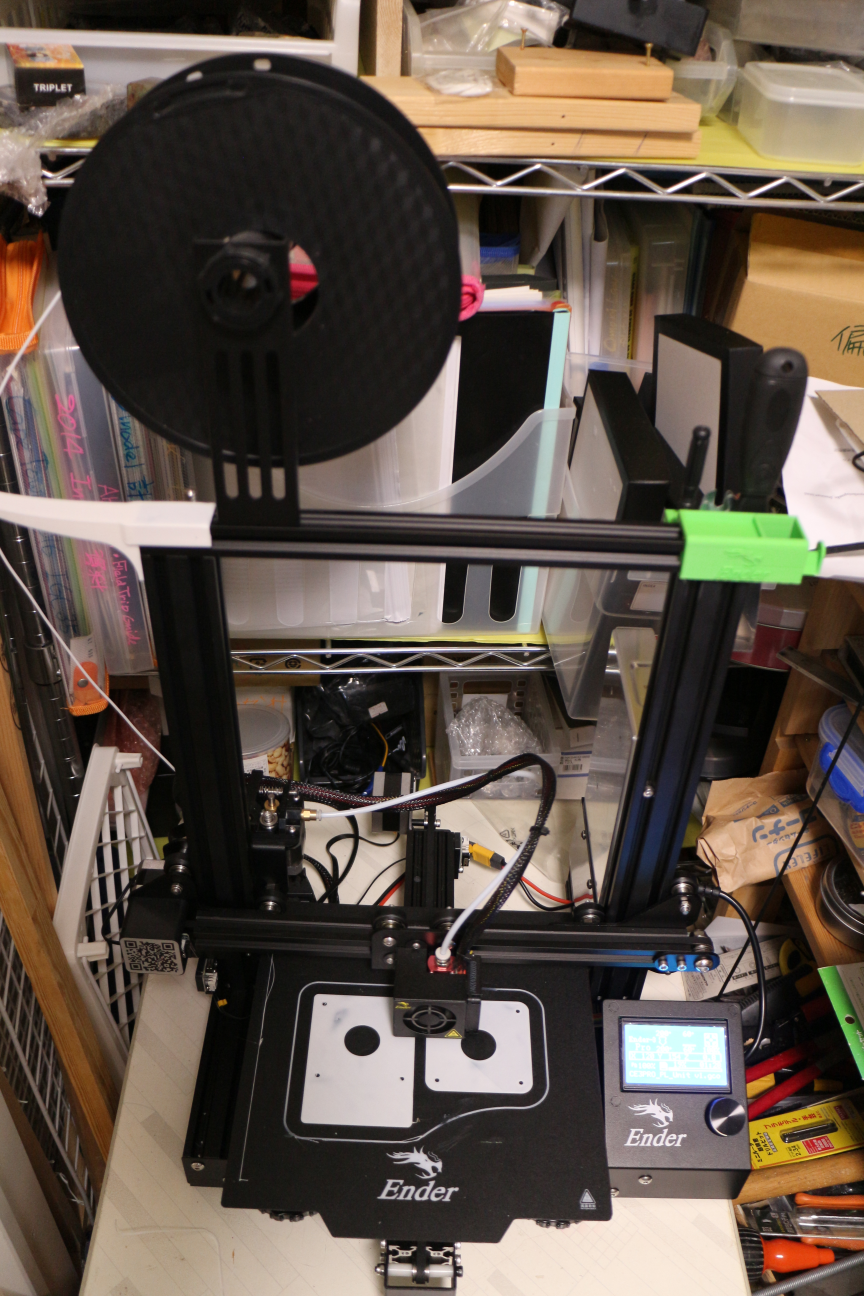

Close up of the blade by a USB

microscope. You can see yellow small diamonds with the tails. The left

hand side is the rotating direction. |

|

|

| The blade is fixed while the another side wet stone handling to stop. (old photo) |

Covered by the table and run water into the tank. We tested our new rock saw successfully, although it began to rain. |

|

|

| After the first test, we check the motor shaft. We found brown rust. And may a little water invades inside. This caused a big problem one year after!, see http://seagull.stars.ne.jp/2020_Thin_Section/Fix_Rock_Saw/index_e.html |

A drain cock hole screw is made with a 8mm tap. |

|

|

| M8 plastic bolt is used as a drain cock. There is no water bleeding now. |

The cutting guide for the tip glued on the slide glass. A thick acrylic plate a and two crumps are used. |

|

|

| Slide glass tip is cutting. Click the image to see a movie! |

The cut tips. Next is second grinding. |