My major is not petrology, but in my undergraduate class, I had a chance

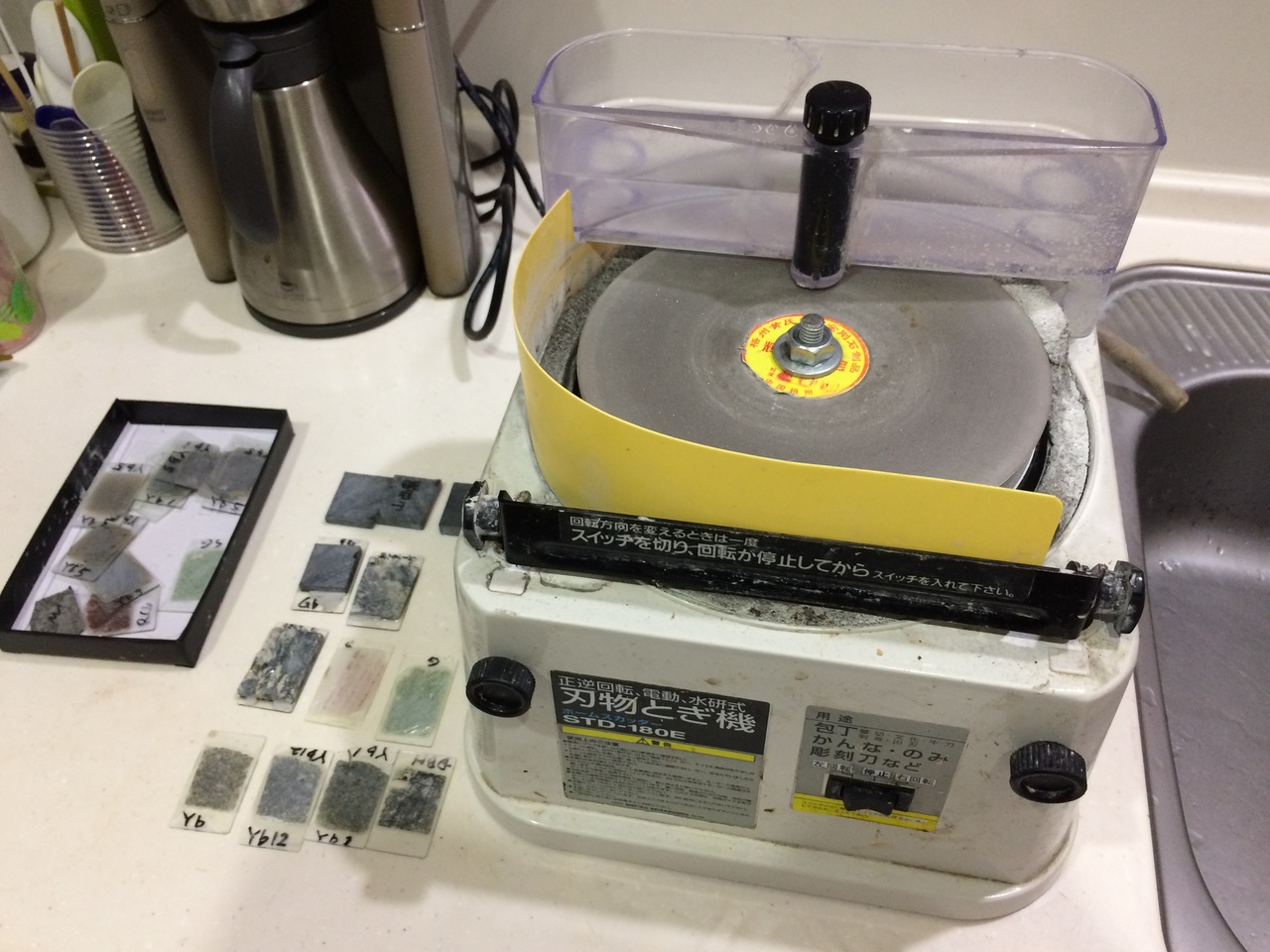

to make thin-sections with the traditional method, which employs

abrasives and a long time tough jobs.

Becoming a geoscience teacher, I spent much time making thin-sections

with our students using a traditional method and a half with a

self-taught way.

Therefore, I try to improve our method through our practices.

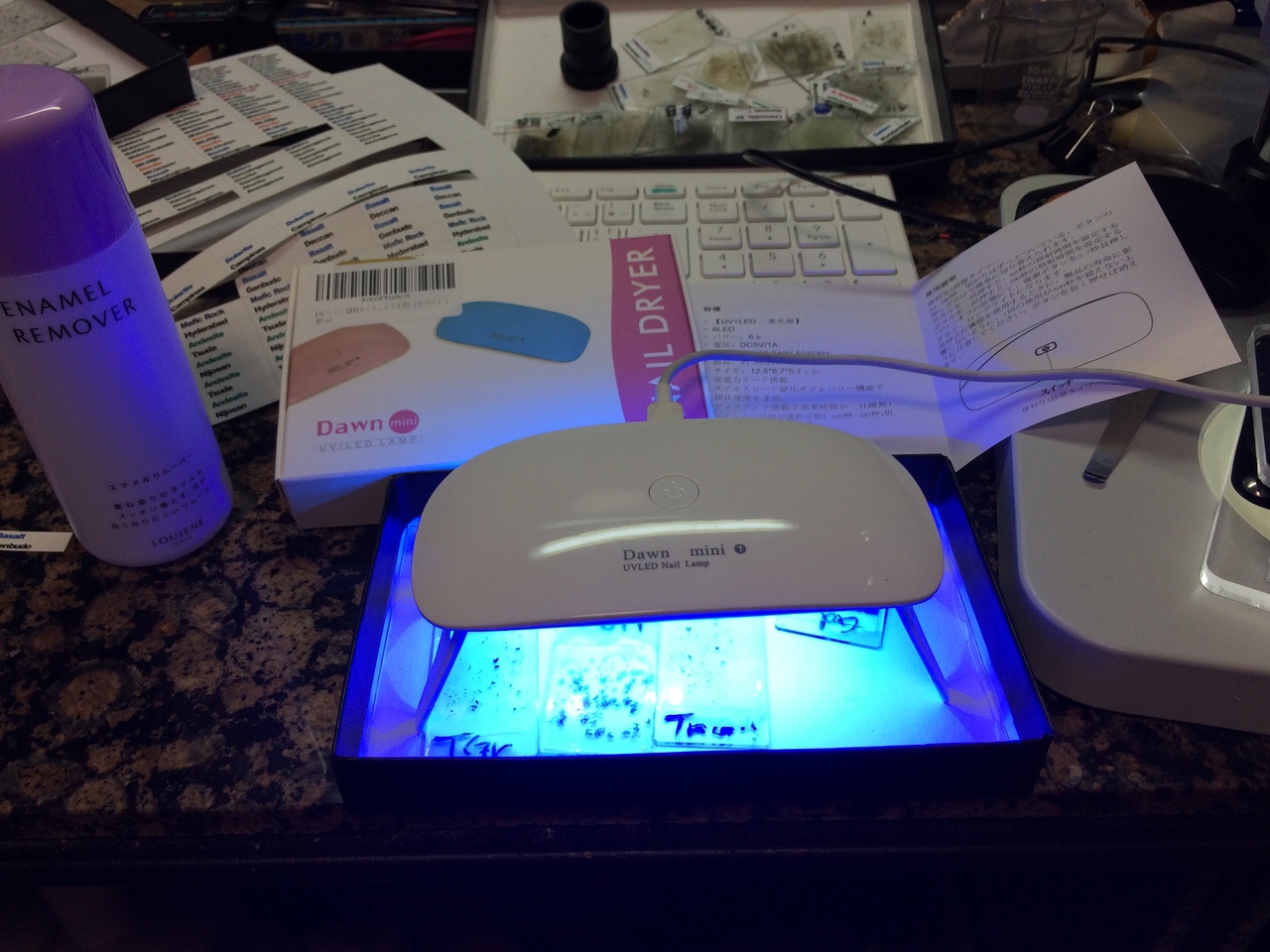

Now, I got a renewal method for classroom use using cheap mass production tools.

This method employs a hybrid method of traditional process and renewed ones

The thin-section making is divided as follows,

The details of the following are, please visit the links!

Part I.(Another page)

1) Sample collection as an appendix of 2)

2) A tip cutting from the sample

Part II. (Another page)

Part III. Important notice!

After long use time our rock saw causes a trouble which the motor bearing is rusted and stuck due to water leak.

In this case, we have to disassemble the motor and change the bearing for repairing.

The detail is here,

http://seagull.stars.ne.jp/2020_Thin_Section/Fix_Rock_Saw/index_e.html

<overview of our new method>

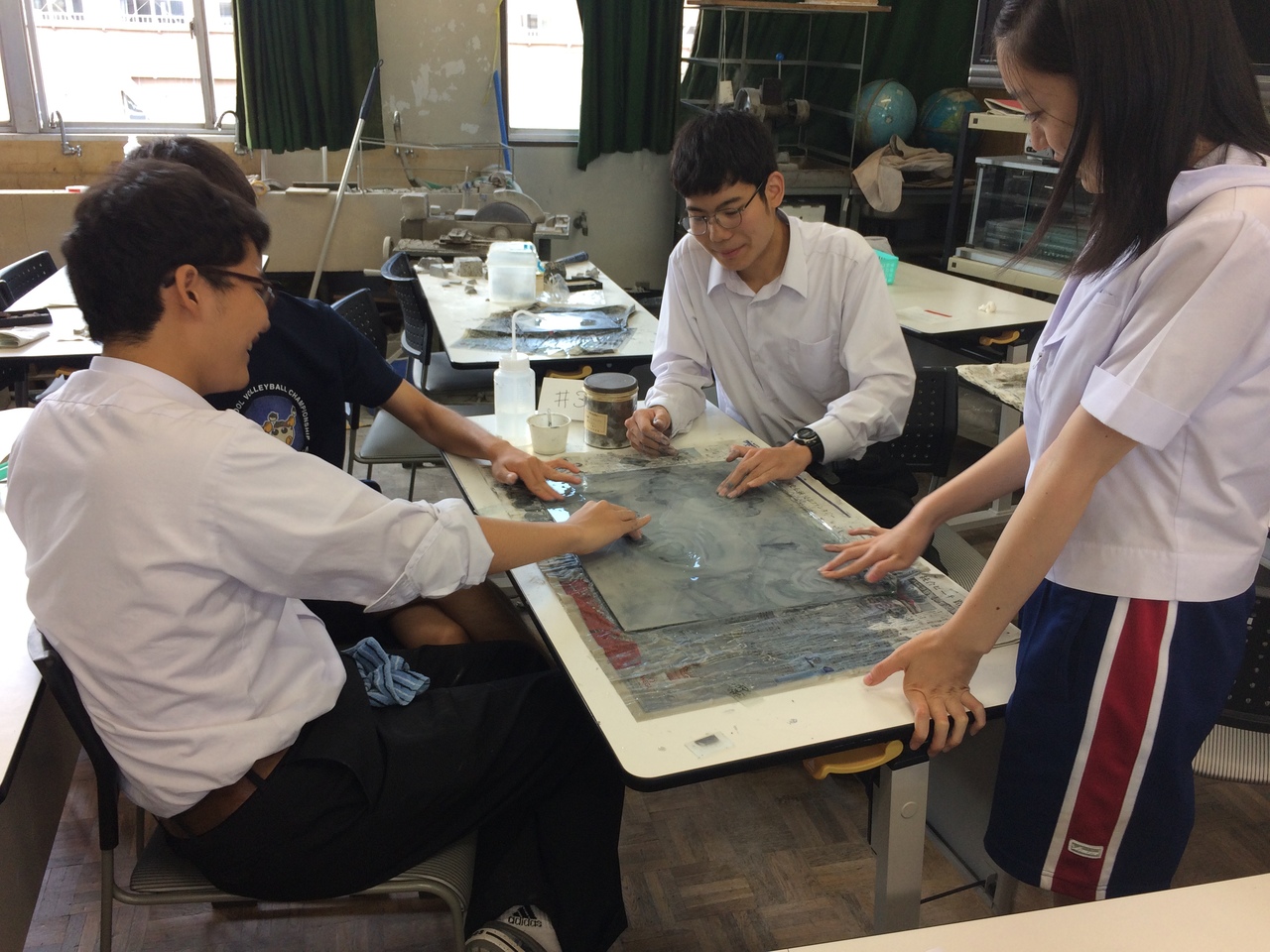

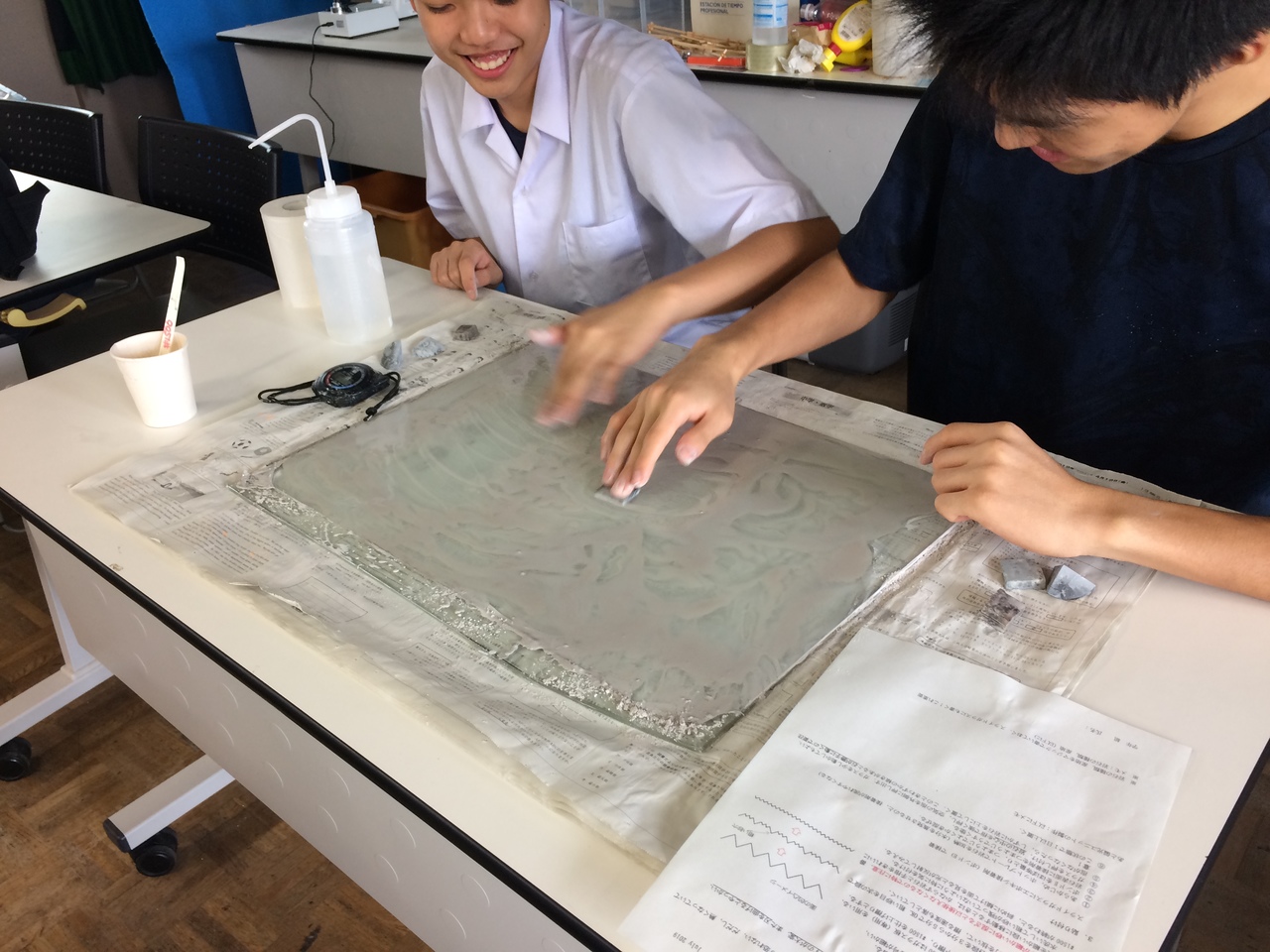

<Traditional (old) Method by our students at Tennoji Highschool attached to Osaka Kyoiku University, June 2019>

|  |

| A professional type rock saw having 250mm diamond blade at Tennoji highschool attached to Osaka-Kyoiku University. | A rock is cut easily by a powerful motor. However, these apparatus is high expensive and very rare to set up these machines in a ordinary secondary school. |

|  |

| Grinding on a glass plate using abrasive #300 carborundum and water as a middle stage. They are enjoying the job and talking! | Grinding on a glass plate using abrasive #1500 arundum and water as a final stage. |

|

| |